Respiratory protective equipment (RPE) is a vital tool for protecting workers from hazardous substances that pose an immediate risk to life and the risk of serious and fatal diseases at a later stage. However, RPE will only provide an effective level of protection if it is carefully selected to match the respiratory hazard, type of work and the physical attributes of the wearers.

Features

Respiratory protective equipment: getting the basics right

Respiratory protective equipment (RPE) is arguably one of the most critical areas of personal protective equipment (PPE). Breathing in certain dusts, gases, fumes and vapours in the workplace can cause serious, long-term lung damage and incurable diseases such as asbestosis, silicosis, chronic obstructive pulmonary disease (COPD), asthma, emphysema and lung cancer, with thousands of cases of chronic lung disease and deaths attributed to work-related respiratory diseases reported every year in the UK.

However, work-related lung disease is preventable, and employers are obliged by law to control the risks to their workers from hazardous substances. Here we consider what health and safety professionals need to know when it comes to RPE by taking things back to basics with the aim of improving understanding and confidence.

Respiratory protective equipment (RPE) is arguably one of the most critical areas of personal protective equipment (PPE). Photograph: Draeger

Respiratory protective equipment (RPE) is arguably one of the most critical areas of personal protective equipment (PPE). Photograph: Draeger

Last line of defence

A good place to start is considering why RPE is needed in the first place and which RPE is adequate to protect against a hazard and suitable for the worker, task and environment.

As context, it is useful to consider the hierarchy of control for managing hazards. PPE – or RPE in the case of respiratory hazards – is considered the last line of defence because it protects the individual wearer from the hazard. RPE should be introduced when removal or substitution for a less hazardous substance is not an option, and when all possible control measures to reduce exposure to the hazard have been introduced (for example, local exhaust ventilation), or for short-term/infrequent tasks, and during installation or repair of control measures.

Hierarchy of control

In such situations, RPE needs to be specified to protect workers from harmful substances such as dust, mist, vapour, gas or fumes. Additionally, specialist RPE may also be needed in areas where oxygen levels are, or may become, low.

Legislation and regulation

The use of RPE is covered in legislation outlining the requirement for employers to provide and maintain a safe working environment, so far as is reasonably practicable, and the basic requirements for this are outlined in both The Health and Safety at Work etc. Act 1974 and The Management of Health and Safety at Work Regulations 1999.

There are also several other key relevant regulations when it comes to RPE, for example The Control of Substances Hazardous to Health (COSHH) Regulations 2002 and specific regulations relating to asbestos, lead, ionising radiations and confined spaces.

Occupational safety and health (OSH) professionals will need to consider the appropriate regulations carefully to reflect how they apply to the environment that they are managing and to ensure compliance with any specific RPE requirements. The Health and Safety Executive (HSE) website provides more detailed information.

When it comes to deciding on adequate respiratory protection equipment, it is important to consider the form of the hazard involved. Photograph: Draeger

When it comes to deciding on adequate respiratory protection equipment, it is important to consider the form of the hazard involved. Photograph: Draeger

RPE selection

There are two broad categories of RPE:

1. Air purifying respirators – sometimes known as filtering devices, which use filters to remove harmful contaminants from the ambient air. These devices can either rely on the wearer’s breathing to draw air through the filter or can use a powered blower unit to draw in the air, pass it through a filter, then supply clean air to a headpiece.

2. Breathing apparatus – this involves a clean supply of air being provided from an independent source such as a cylinder or breathing quality airline.

Identifying which type of RPE is both adequate and suitable for any given scenario is an important part of getting RPE selection right and there are several steps to take.

Let us consider first whether the RPE is adequate:

This addresses the questions of whether the RPE protects against the form and type of hazards present and whether it offers the necessary protection factor to ensure that the workplace exposure limit (WEL) is not exceeded and that exposure is reduced to as low a level as possible.

Step 1: Identify the exposure hazard

It is necessary to identify the hazardous substance present and the amount of it that is in the air (the exposure level). Airborne hazardous substances can be caused by either products classed as ‘dangerous for supply’ or from work activities that contaminate the air, such as grinding, cutting or heating materials, or handling dusty powders. There may be documents in place that will provide the information required, such as COSHH risk assessments drawn up for work tasks involving hazardous substances, Safety Data Sheets supplied with chemical substances or COSHH Essentials guidance published by HSE to offer basic advice.

Step 2: Determine if the task is in oxygen deficient or IDLH atmospheres

To determine whether air purifying respirators (APR) are suitable for a given scenario, safety professionals will need to understand whether certain conditions can be met:

- There must be a minimum level of oxygen: 19.5 vol. per cent (UK)

- The area must not be poorly ventilated or a confined space (for example, tanks, small rooms, tunnels or vessels)

- The type and concentration of contaminant must be known

- The contaminant must have clear warning properties such as a noticeable smell or taste

- The contaminant must not be a above a level that is immediately dangerous to life and health (IDLH).

Where these conditions are not met APR is not appropriate and specialist breathing apparatus such as self-contained breathing apparatus (SCBA) using cylinders or airline systems will need to be specified, with those using such systems given appropriate training.

Step 3: Identify the form of the hazardous substance.

When it comes to deciding on adequate respiratory protection equipment, it is important to consider the form of the hazard involved – for example particulates such as dust, as opposed to gas or vapour – to ensure that the correct protection is offered. These are usually present in three forms:

1. Particles: sometimes referred to as ‘aerosols’ which describes the suspension of a solid or liquid particle.

2. Vapours: a gaseous form that has vaporised from liquid such as a solvent, even when it is below the boiling point.

3. Gases: a substance that is in a gaseous form under normal conditions – i.e. sulphur dioxide or chlorine.

Step 4: Match filters to the hazardous substance and its form

Choosing filters can be daunting, so it helps to understand that there are two different types of filter material (for particles or for gas/vapour), and that filters are divided into three classes in relation to the form of the hazardous substance/s that they are to be used to guard against:

1 – Particles

2 – Gas/vapour

3 – Combi – combined particle and gas/vapour.

Filters and filtering devices are divided into these classes based on their filtering efficiency (particle filters) their capacity (gas filter) and the total inward leakage for the device type.

It is easy to recognise respirator filters as they are labelled with standard colour coding used throughout Europe in accordance with the EN 14387 standard. This enables duty holders and RPE users to instantly recognise which type of protection each filter provides. Different protection levels are offered to help balance out other factors, such as breathing resistance or the weight of the filter, to encourage more workers to use their RPE rather than offering the highest level of protection in every case. The lower levels must still offer adequate protection for the hazard.

Step 5: Decide on the Protection Factor

Those specifying RPE will also need to understand the level and duration of exposure to a hazard over both a working shift and longer-term. The ratio of this exposure and the workplace exposure limit (WEL) can be used to calculate a minimum required Protection Factor for the RPE. This can help determine the type and class of protection needed.

To find an assigned protection factor (APF) firstly consult the COSHH guidance from HSE or any available safety data sheets (SDS) – these may provide the appropriate APF for protection against a hazardous substance for a specific task. Where no rating is provided, it will be necessary to calculate the required protection factor (RPF) with data gathered from occupational exposure monitoring.

In some cases, such as working with carcinogens, or respiratory sensitisers (substances that can trigger an allergic reaction in the respiratory system upon inhalation, leading to conditions like occupational asthma), it is necessary to reduce exposures to as low as reasonably practicable (ALARP), at which point the aim should be to reach exposures much lower than the WEL.

Secondly, let us consider whether the RPE is suitable:

This question addresses whether the RPE is the right option for the wearer, the task and the environment, and introduces the idea of suitability factors.

In relation to the wearer, suitability factors can include anything that would affect face fit testing, including face size and shape and facial hair, as well as considerations such as any medical conditions a wearer may have. For the task, suitability factors might include wear time (how long a wearer will need to wear the RPE) and work rates (how labour intensive the task is). Suitability factors that are affected by the environment include ambient temperatures and the requirement for other PPE (any RPE that is specified must be compatible with other PPE that is being worn).

Many suitability factors that can affect RPE selection are well known and even documented in guidance such as the HSE’s ‘HSG53’ booklet, Respiratory protection at work: A practical guide.

Respiratory programme management (RPM)

Finally, when recommending any RPE it is worth considering how it is to be managed, and its roll-out implemented with users. An effective RPM should include wearer engagement, support and training, and cleaning, maintenance and storage. Done effectively, the process can help to create a positive safety culture with engaged, compliant wearers, and all involved will be confident in the specification of RPE that is adequate and suitable.

For more information see:

draeger.com/en_uk/Productfinder/Respiratory-Protection

Ian Kelsall is RPE technical specialist at Draeger Safety UK

FEATURES

How to mitigate the hearing loss cost escalation tsunami

By Peter Wilson, Industrial Noise and Vibration Centre (INVC) on 06 February 2026

Employers need to adopt the latest and most effective noise risk evaluation and management measures, or face rapidly-rising compensation claims for noise-induced hearing loss at work.

Young drivers and work-related road risk: why employers must act now

By Simon Turner, Driving for Better Business on 06 February 2026

Young drivers have a higher risk of being involved in road collisions due to factors such as their inexperience, so when employing them to drive for work, it is vital they receive the right support to help them grow into safe professionals behind the wheel.

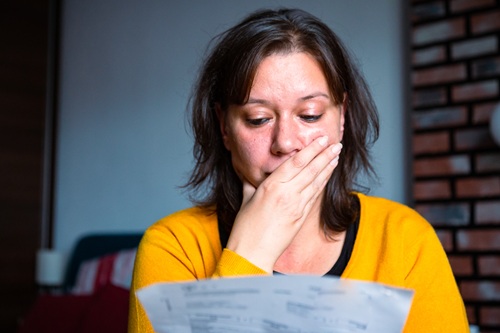

Financial stress: why and how it affects workplace safety

By Chloe Miller, freelance writer on 06 February 2026

Financial worries can lead to cognitive impairment that increases the risk of workplace accidents, so it’s essential employers provide financial education and confidential support for workers who may be struggling with problems like debt and unexpected living expenses.