Smart hearing protection technology can provide feedback to workers on harmful noise levels and identify noise sources overlooked by conventional workplace risk assessments, as shown by recent research on the HS2 railway construction project.

Features

How smart hearing protection is driving reductions in noise exposure at work

Great Britain’s health and safety performance has seen significant improvements over the past 30 years. However, Health and Safety Executive (HSE) statistics show that each year over a million workers are injured or made ill by their work. This affects individuals, families, employers, government and wider society.

Technology is changing rapidly and should be embraced to keep the workplace a safer and healthier place for all. ‘Industrial Safetytech’ is the term for innovative technologies, products and services that are redefining approaches to health and safety management. It can play a crucial role in promoting compliance with health and safety legislation. However, regulations established to protect the public interest can become barriers to innovation. Addressing this potential regulatory barrier requires regulators and innovators to collaborate, to promote and stimulate emerging technology.

Photograph: Eave

Photograph: Eave

In response to this challenge a project was devised that employs a regulatory sandbox approach enabling experimentation with technological innovations. It benefits both regulator and industry, providing clarity to innovators on regulatory expectations and confidence to industry to invest in and adopt Industrial Safetytech.

HSE leads this ground-breaking project in partnership with Safetytech Accelerator (an organisation dedicated to advancing safetytech in industry), to generate practical evidence-based assessments of Industrial Safetytech against regulatory frameworks in construction. The project outcomes support safe deployment of emerging technology providing confidence to large business and SMEs around the adoption of Industrial Safetytech.

Six tech companies, from an initial field of more than 200, were chosen via the Sandbox selection criteria to participate in investigative studies. One of these companies was Eave – Eave’s project aimed to provide a comprehensive understanding of noise-induced hearing loss (NIHL) in the context of workplace safety and explore the potential benefits of incorporating new technology into the regulatory framework.

The project set out three core questions to be answered within the Sandbox:

- What are the potential contributing factors to the under-reporting of NIHL?

- How can smart hearing protection technology contribute to the prevention of NIHL, and is it reasonably practicable to implement it as a control measure in place of traditional hearing protection?

- How should the guidance on reasonable practicability be updated to account for technological advancements in hearing protection, and what are the implications for businesses and regulatory bodies?

The Eave system consists of smart ear defenders which collect data on personal hearing protection wear rates, at-ear noise dosimetry, environmental noise levels, and personal attenuation rating while also mapping worksite noise. The system is used to protect workers from harmful levels of noise, adjust working methods and remove noise hazards at source.

The extent of overexposure

The project spanned various scopes of work within the HS2 (High Speed 2 UK railway line) early works contracts, including demolition, ground works, temporary works and utilities. The findings, as introduced in the table below, underscore the stark reality of extremely high levels of dangerous noise exposure across the contractor group. The smart hearing protection devices issued to workers for the trial played a crucial role in revealing the extent of overexposure, shedding light on instances where the combination of hearing protection use behaviours, high noise levels and prolonged exposure surpassed healthy thresholds.

This examination of overexposure is paramount for developing targeted interventions and ensuring the wellbeing of workers in high-risk environments. The findings and implications of the observed overexposure emphasise the need for strategic measures in safeguarding the health and safety of workers in diverse occupational settings.

Identifying reasons for under-reporting

The under-reporting of NIHL poses a significant challenge in workplace safety, hindering effective prevention and mitigation efforts. Identifying the reasons behind this under-reporting is crucial for developing targeted strategies to address and rectify the issue.

The project uncovered a number of multifaceted factors that contribute to the under-reporting of NIHL, which are highlighted below. From a lack of awareness among workers and employers to challenges in establishing causality, each factor sheds light on the intricate web that conceals the true extent of NIHL in occupational settings. Understanding these underlying issues is paramount in crafting comprehensive solutions that not only tackle the immediate concerns but also address the root causes of under-reporting.

The key factors influencing the under-reporting of NIHL and their implications for workplace safety and employee wellbeing, as highlighted by the research among workers on HS2 overseen by Safetytech Accelerator, HSE and Eave, are:

- Lack of awareness: When workers and employers do not understand the risks and symptoms of NIHL, they cannot accurately identify the condition or prioritise prevention measures. This lack of awareness can lead to an underestimation of the impact of noise exposure.

- Delayed onset: NIHL typically develops gradually over time, making it hard for workers to establish a clear connection between their hearing loss and their exposure to noise at work. Because there are not always immediate symptoms such as tinnitus (ringing in the ears), individuals may not consider workplace noise as the source of their hearing loss.

- Stigma and fear of job loss: The fear of stigma associated with hearing loss and potential job loss can deter individuals from reporting NIHL. Many workers hide their symptoms or fail to seek help due to concerns over job security and fear of being perceived as weak or less capable.

- Inadequate noise exposure assessments: If the methods used to assess noise exposure in the workplace are inaccurate or incomplete, it can lead to underestimating the risk of NIHL. Inaccurate assessments mean that dangerous levels of noise can go undetected, and workers exposed to these noise levels might not realise they’re at risk.

- Insufficient enforcement and compliance: When there is inadequate enforcement of regulations, workers are more likely to be exposed to harmful noise levels. In turn, this increases the likelihood of under-reporting of NIHL as workers may not realise the extent of their risk.

- Challenges in establishing causality: Identifying the exact cause of NIHL can be complex due to various potential confounding factors such as genetics, medications and other sources of noise exposure. This difficulty can discourage workers from reporting their hearing loss as they may not attribute it directly to their workplace noise exposure.

- Misdiagnosis or lack of diagnosis: NIHL symptoms can be similar to other forms of hearing loss. Without proper diagnosis, workers suffering from NIHL may believe they have a different type of hearing loss that is not work-related, leading to under-reporting.

- Absence of immediate effects: The gradual nature of NIHL often results in a lack of immediate symptoms. This delayed reaction can make it harder for individuals to link their hearing loss to their workplace noise exposure, leading to under-reporting.

- Lack of accessible reporting channels: If the process for reporting NIHL is complicated or not clearly communicated, workers may feel discouraged or confused about reporting their symptoms, resulting in under-reporting.

- Limited healthcare access: In regions where healthcare services are less accessible, routine health check-ups and hearing tests that could detect NIHL are less likely to occur. This can lead to many cases of NIHL going undiagnosed and unreported.

- Age-related misconceptions: Some individuals might attribute their hearing loss to age rather than their exposure to noise. This misconception can result in many cases of NIHL being misattributed and under-reported.

- Compensation systems: Navigating workers’ compensation systems can be daunting and confusing. If workers find it difficult to claim compensation for NIHL, they may choose not to report their symptoms.

- Failure to recognise early symptoms: Early signs of NIHL, such as tinnitus or temporary threshold shift, can be easily overlooked. Workers might dismiss these symptoms as minor or temporary, not recognising them as signs of ongoing noise damage, leading to under-reporting.

The impact of smart hearing protection on PPE wear rates

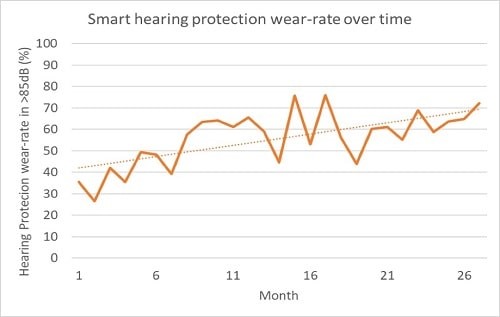

Wear rates of PPE increase significantly over time:

The introduction of smart hearing protection devices has been instrumental in transforming the landscape of personal protective equipment (PPE) wear rates among workers. Traditionally, PPE adherence faced challenges, with wear rates often dwindling over time due to factors such as discomfort, inconvenience or a perceived lack of an immediate need to wear protection. However, the integration of sensors and data gathering to create smart hearing protection has initiated a notable shift in this paradigm.

The real-world feedback provided by these smart devices on noise exposure serves as a powerful motivator for operatives. Unlike conventional hearing protection, the smart technology not only shields individuals from hazardous noise levels but also informs them of their exposure levels. This direct feedback creates a heightened awareness among operatives regarding the potential risks associated with noise, fostering a sense of responsibility towards their own wellbeing.

Source: Eave

Source: Eave

Positive behaviours during operation:

The direct feedback loop established by smart hearing protection devices triggers positive behaviours among operatives while they are engaged in various operations. As individuals become more cognisant of their real-world exposure levels, a natural inclination towards proactive safety measures emerges. This heightened awareness encourages operatives to consistently wear their PPE, recognising it as an indispensable tool for safeguarding against the harmful effects of noise.

Operatives, armed with the knowledge of their exposure levels, are more likely to prioritise the consistent use of smart hearing protection, creating a positive feedback loop. This shift in behaviour not only enhances individual safety but also contributes to a more robust safety culture within the workplace. The proactive engagement with PPE becomes a shared responsibility, further reinforcing the importance of adopting and maintaining protective measures throughout the duration of tasks.

In essence, the impact of smart hearing protection on PPE wear rates transcends the conventional challenges associated with compliance. The integration of real-world feedback not only addresses comfort and convenience concerns but actively cultivates a culture of safety consciousness among workers, leading to a significant and sustained increase in the wear rates of essential protective equipment.

Source: Eave

Source: Eave

Wear rates of smart hearing protection increase significantly over time (see graph). The direct feedback of noise exposure causes an increase in positive behaviours by operatives during operation.

New sources of noise were discovered

Identification through noise mapping functionality:

A pivotal outcome of the project was the revelation of previously unrecognised sources of noise hazards through the utilisation of advanced noise mapping functionality. The comprehensive assessment provided by the Eave technology proved instrumental in uncovering nuanced details that had initially escaped scrutiny during the formulation of the risk assessment and method statement (RAMS). The integration of noise mapping added a further layer of insight to the evaluation process, offering a dynamic perspective that went beyond the scope of traditional risk assessments.

Overlooked areas in initial RAMS:

The project highlighted instances where potential noise hazards were overlooked in the initial RAMS. The identified areas encompassed diverse operational facets, such as the utilisation of a jet wash, the presence of a hot works burner and activities conducted in basements. These activities, while integral to the overall operation, were not adequately accounted for in the initial risk assessment, resulting in the generation of unplanned noise hazards.

These unplanned sources of noise posed a potential risk to the wellbeing of operatives, emphasising the need for a more adaptable and responsive approach to noise management.

Photograph: Eave

Photograph: Eave

Visual representation of newly identified areas:

The visual representation, as depicted in the map of the site above, vividly illustrates the newly identified areas of exposure marked in red. This mapping not only serves as a valuable tool for immediate risk mitigation but also provides a visual reference for future risk assessments and operational planning. The incorporation of such visual aids enhances the precision of identifying potential noise hazards, offering a comprehensive overview that aids in proactively addressing and managing risks in real-time.

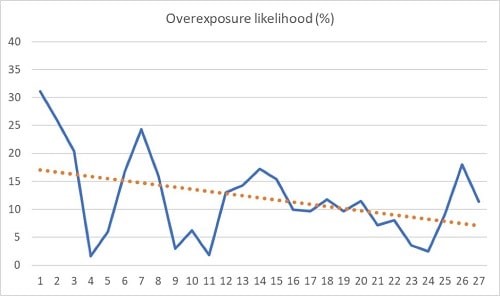

Contractors began to remove noise identified at source

The commitment to addressing noise exposure at its source was exemplified by one HS2 subcontractor’s efforts. Over a substantial period of 694 days, the subcontractor was able to readily utilise 7,000 hours of data analysed using the Eave technology related to noise exposure. This comprehensive dataset provided a clear understanding of the patterns and trends associated with operatives’ exposure to noise hazards.

Within the dataset, an alarming revelation surfaced – on 21 per cent of the observed days, operatives subjected themselves to overexposure to noise. This finding translated into 148 specific incidents of overexposures during the monitored timeframe. This not only highlighted the prevalence of the issue but also underscored the urgency of addressing it to safeguard the wellbeing of the workforce.

The insights derived from the platform data played a pivotal role in raising awareness among the subcontractor’s management and workforce. The realisation that a significant proportion of operational days resulted in overexposure incidents prompted an immediate and proactive response. In response to this newfound awareness, the RAMS underwent a thorough review.

The review of RAMS, informed by the data-driven insights, led to strategic decisions aimed at addressing the issue at its core. Specifically, management implemented measures to relocate workers from high-risk noise exposure areas to those with lower hazard levels. This relocation was a direct response to the identified overexposure incidents, demonstrating a commitment to worker safety and an agile approach to risk mitigation.

This led to a halving in the overall level of exposure for workers

The decisive actions taken in response to the identified overexposure incidents were not merely reactive but formed a strategic plan to overhaul the working conditions. The relocation of workers from high-risk noise exposure areas, coupled with the review and adaptation of the RAMS, demonstrated a commitment to addressing noise hazards at their root. This strategic approach ensured a comprehensive and lasting impact on the overall exposure levels for workers.

The specific and data-informed measures implemented were not generic but tailored to the insights gained from the data collection. This precision in mitigation efforts, such as relocating workers to lower hazard areas, directly contributed to a targeted reduction in exposure. By addressing the identified sources of overexposure, the organisation demonstrated an ability to enact precise and effective changes, resulting in a more controlled and manageable work environment.

Actions led to a halving of overall exposure levels for workers. Source: Eave

Actions led to a halving of overall exposure levels for workers. Source: Eave

The outcome of these strategic interventions was starkly evident in the trial group’s exposure levels. The measures taken, informed by the data-driven insights, led to a noteworthy accomplishment – a halving of the overall exposure levels for workers (see graph). This quantifiable reduction underscored the tangible success of the implemented measures and validated the effectiveness of the organisation’s commitment to enhancing workplace safety.

The success in reducing exposure levels was not treated as a final achievement but rather as a milestone in an ongoing commitment to worker safety. The organisation’s ability to continuously monitor and adapt based on emerging data and insights ensures that the positive impact on exposure levels is sustained over time. This commitment to a dynamic and evolving approach solidifies the organisation’s dedication to creating a consistently safe and healthy work environment.

Key learnings

Prevalence of overexposure in construction:

The revelation that overexposure to noise is widespread within the construction industry serves as a wake-up call, challenging the official figures reported. This stark contrast highlights a significant discrepancy between the actual extent of noise-related hazards in construction and the reported incidents. The acknowledgment of this dissonance emphasises the urgency of re-evaluating existing practices and adopting more accurate methodologies for assessing and addressing noise-induced hearing loss (NIHL) within the sector.

The profound implications of these findings reverberate throughout the construction industry, necessitating a fundamental shift in the approach to occupational health and safety. The discrepancy between observed overexposure and reported incidents suggests an inherent challenge in accurately capturing and addressing the true scope of NIHL. Recognising and addressing this disconnection becomes imperative for fostering a workplace culture that prioritises the wellbeing of its workforce.

Dr David Greenberg is founder and director of Eave. Photograph: Eave

Dr David Greenberg is founder and director of Eave. Photograph: Eave

The identified disparity underscores the multifaceted nature of under-reporting, prompting a strategic reevaluation of current practices. The key insights gleaned from the trial suggest that addressing the under-reporting of NIHL involves a comprehensive approach. Raising awareness among workers and employers about the risks and symptoms of NIHL emerges as a crucial first step. Improving the accuracy of noise exposure assessments, tackling stigma and fears associated with reporting, and simplifying the reporting process are identified as pivotal measures to rectify under-reporting effectively.

The necessity of raising awareness within the industry about the prevalence and consequences of NIHL cannot be overstated. By fostering a culture of openness and understanding regarding the risks posed by noise exposure, the industry can empower workers to actively participate in their own safety. Heightened awareness serves as a catalyst for a proactive approach to hearing protection, encouraging individuals to report symptoms and contribute to a more accurate representation of the true state of occupational hearing health.

The findings reinforce the need for a holistic approach to noise exposure management within the construction sector. This includes not only implementing advanced technologies for real-world monitoring but also addressing the underlying factors that contribute to under-reporting. By systematically dismantling barriers such as stigma, fear, and inadequate reporting processes, the industry can create an environment where the true extent of NIHL is recognised, reported, and mitigated effectively.

Recommendations, actions and impact

For the HSE

- Noise exposure assessments and investigations – reasonable practicability

The project findings indicate that smart hearing protection data could be used to replace traditional methods of noise exposure assessment, such as the HSE Noise Exposure Ready-Reckoner. Data from smart hearing protection offers a more comprehensive approach to assessing noise exposure levels in the workplace. By continuously monitoring noise exposure both inside and outside of the hearing protection devices, the Eave platform provides real-world data on workers’ noise exposure levels. This information can be used to inform appropriate noise control measures and ensure compliance.

For industry

- Raising the bar

The findings of this project have profound implications for the industry, as they underscore the necessity of addressing the myriad factors leading to the under-reporting of NIHL. Raising awareness about NIHL, improving noise exposure assessments, addressing stigma and fears, and simplifying the reporting process are vital steps to rectify underreporting. These actions should be accompanied by efforts to enhance compliance with noise exposure regulations and improve access to healthcare services. It has been demonstrated that the use of smart hearing protection can help reduce the risk of NIHL. Thus, the insights from smart hearing protection data should also inform the development and implementation of more effective and targeted noise control measures.

Dr David Greenberg is founder and director of Eave

For more information see:

- +44 7952 925540

FEATURES

How to mitigate the hearing loss cost escalation tsunami

By Peter Wilson, Industrial Noise and Vibration Centre (INVC) on 06 February 2026

Employers need to adopt the latest and most effective noise risk evaluation and management measures, or face rapidly-rising compensation claims for noise-induced hearing loss at work.

Young drivers and work-related road risk: why employers must act now

By Simon Turner, Driving for Better Business on 06 February 2026

Young drivers have a higher risk of being involved in road collisions due to factors such as their inexperience, so when employing them to drive for work, it is vital they receive the right support to help them grow into safe professionals behind the wheel.

Financial stress: why and how it affects workplace safety

By Chloe Miller, freelance writer on 06 February 2026

Financial worries can lead to cognitive impairment that increases the risk of workplace accidents, so it’s essential employers provide financial education and confidential support for workers who may be struggling with problems like debt and unexpected living expenses.