Drones are starting to play a revolutionary role within the inspection industry, but scepticism and misunderstanding about their capabilities and deployment is an issue.

Features

Eyes on the sky

How can the strategic adoption and correct utilisation of drones elevate the inspections process and lead to a safer, faster and better blended approach?

The use of drones is expected to have a significant impact on the construction and manufacturing industries, with an estimated of £8.6 billion GPD uplift in the UK alone by 2030. There is also the efficiency they can bring to a process; it is estimated that site surveys can be a lot quicker using drones, compared to traditional, labour-intensive surveying, according to Sky’s the limit as drones take inspection to new heights, a report published by PwC in 2018.

When it comes to inspection, drones offer a number of invaluable capabilities and benefits if used in combination with traditional methods of assessment and supervision. There are two distinct advantages of using drones in inspection; as an access solution and for assessment of a building condition.

Using drones can be an efficient and effective method of conducting an initial visual assessment of large or difficult- to-access location or equipment, at minimal risk and without disrupting the work on the site. If deployed as an extension of the engineering inspector’s eyes and using a technically competent operator on the ground, drones can add value by efficiently identifying particular defects or areas of concern, or safety risks that require further assessment by an inspector.

As new systems and equipment are regularly introduced, inspectors are now navigating through more complex spaces, which can prove challenging. In some cases, to access may require closing off a section of a facility or shutting down completely for a period of time, which can lead to costly downtime – as well as being inconvenient and taking longer.

In these instances, using a drone for an initial assessment may reduce the need for equipment such as Mobile Elevated Work Platforms (MEWPs) and scaffolding, and allow the engineering inspector visual access quickly and easily.

Drones are also now capable of close-up surveillance of even the tallest and most inaccessible structures; or on the opposite circumstances, of confined internal spaces such as large tanks, warehouses, roof spaces, boilers and cellars, where they can be used to pick up on minute yet highly important details including corrosion and cracking.

The latest advances in collision-resistant and collision-tolerable unmanned aerial vehicles (UAV) also enable them to ‘bounce’ off surfaces and roll along walls without getting damaged or damaging the structure.

This capability for coping with the challenges of demanding environments can save valuable resources. A drone can assess an entire site in a fraction of the time that a traditional method would, even in challenging weather conditions. The result can be an inspection that delivers a complete overview of a building’s infrastructure while meeting all relevant regulatory requirements.

In terms of a building condition assessment, the deployment of drones is ideal for monitoring the construction progress and creating a record of data for the future. As well as efficiently conducting a visual assessment, drones can also collect three-dimensional information that can be integrated with existing building information modelling (BIM) systems and original design CAD to offer another layer of advantage for the customer.

Industry adoption

Despite their potential in terms of improving accessibility and efficiency, many sectors have been slow to adopt the use of drones in inspections and surveying, mainly down to a misconception that it is still a relatively new technology with an unproven track record compared to other tried and tested methods.

Others, meanwhile, believe the process is too complex, involving many risks such as complying with the Civil Aviation Authority’s (CAA) strict airspace restrictions.

In reality, while the initial set up can, indeed, be complicated, certification and inspection specialists have the expert skills and knowledge, underpinned by a clear and concise system in place to advise clients of some of the working conditions required to operate drone inspections – making the whole process seamless and easy to implement.

When it comes to embracing drones, it’s clear that early adoption is crucial, and this blended approach to inspection using technology will no doubt become more commonplace. The use of drones presents a myriad of opportunities to make the process of testing and inspection much safer, better and faster, especially for companies looking to stay ahead of the curve when it comes to best practice and retaining their competitive edge.

Kyle Veitch

Technical, quality & risk director for North West Europe

Bureau Veritas

FEATURES

How to mitigate the hearing loss cost escalation tsunami

By Peter Wilson, Industrial Noise and Vibration Centre (INVC) on 06 February 2026

Employers need to adopt the latest and most effective noise risk evaluation and management measures, or face rapidly-rising compensation claims for noise-induced hearing loss at work.

Young drivers and work-related road risk: why employers must act now

By Simon Turner, Driving for Better Business on 06 February 2026

Young drivers have a higher risk of being involved in road collisions due to factors such as their inexperience, so when employing them to drive for work, it is vital they receive the right support to help them grow into safe professionals behind the wheel.

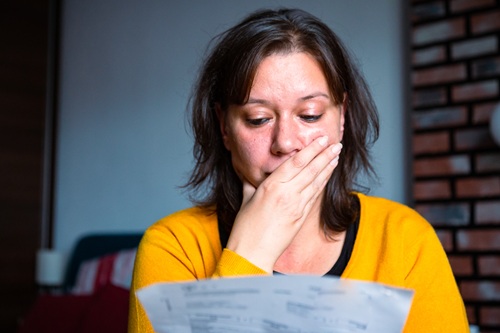

Financial stress: why and how it affects workplace safety

By Chloe Miller, freelance writer on 06 February 2026

Financial worries can lead to cognitive impairment that increases the risk of workplace accidents, so it’s essential employers provide financial education and confidential support for workers who may be struggling with problems like debt and unexpected living expenses.