The risk of workers suffering hearing damage from harmful levels of noise at work could be slashed by as much as 90 per cent by adopting the latest noise control best practice techniques.

Features

Protecting workers’ hearing: it’s time to change our approach

Noise-induced hearing loss (NIHL) caused by exposure to loud noise from plant, machines and tools is preventable, so why do so many employees still suffer unnecessary hearing damage? The simple answer is that the current noise risk reduction practices adopted by employers are often ineffective and need to be updated.

Current noise risk reduction practices have not been effective despite the continuing expenditure on noise assessments and personal hearing protection (known as PPE, or personal protective equipment, like earmuffs and earplugs). NIHL is estimated to cost the UK economy around £25 billion a year. Recent research has also revealed that if you have moderate hearing loss, the risk of developing dementia increases by three times – making hearing loss the largest single modifiable risk factor for dementia – i.e. a risk we can prevent or reduce.

Why do you repeat risk assessments, most of which are poor quality placebo exercises telling you what you already know: that you still have a noise problem? Photograph: iStock

Why do you repeat risk assessments, most of which are poor quality placebo exercises telling you what you already know: that you still have a noise problem? Photograph: iStock

However, combining the latest research, innovations and expertise from INVC (Industrial Noise & Vibration Centre), EAVE (a developer and manufacturer of personal hearing protection) and Hearing Services (a health surveillance provider), has generated revised NIHL prevention best practices.

If employers were to introduce the following three updates to the typical NIHL prevention processes most of them currently follow, the risk of workers suffering NIHL would be reduced by 75-90 per cent – quickly and while staying within the current typical level of employer expenditure on noise control measures.

The first step is to ask yourself these questions:

Assessments and noise control

- Why do you repeat risk assessments, time-and-again – most of which are poor quality placebo exercises (according to HSE research), telling you what you already know: that you still have a noise problem?

- Do your past noise reports include a defined and prioritised action plan to reduce the risk to hearing health from noise with timescales and responsibilities?

- Has anyone ever carried out an audit to generate a noise control cost/benefit analysis? This is a regulatory requirement.

- Why is it assumed that noise control is not practical? Knowledge of modern, low-cost engineering noise control techniques is abysmal. Consequently, noise levels, and therefore risks, are not reduced.

- How much do you spend on noise reports?

Hearing protection – actual performance

- There is an assumption that conventional PPE guarantees adequate protection. It often doesn’t so staff unwittingly suffer unnecessary damage.

- What is the wear rate (the actual amount of time hearing protection is worn by workers when it is required) in Noise Hazard Zones? If you don’t track this, you have no idea of the protection provided by the PPE.

- What is the actual employee field protection being achieved (the actual level of protection against noise provided by the PPE)? This is in no way related to the PPE suppliers’ assumed protection values (i.e. the PPE suppliers’ data on the noise reduction, or attenuation, the equipment theoretically provides).

- How much do you spend on hearing PPE per year?

It is almost impossible to guarantee adequate protection from hearing damage when wearing PPE if noise levels are above 90dB(A). Photograph: iStock

It is almost impossible to guarantee adequate protection from hearing damage when wearing PPE if noise levels are above 90dB(A). Photograph: iStock

Audiometry – who benefits?

- Have you considered that conventional audiometry (the provision of regular hearing checks for workers at risk of hearing damage due to noise exposure, known as health surveillance), is largely a placebo checkbox exercise as it provides too little information too late to be of use in noise exposure risk management? It doesn’t have to be.

- How often do you carry out audiometry and how much does it cost per year?

- Have the results of audiometry ever been used to change noise control policy or actions?

The three changes necessary for achieving ‘Nil NIHL’

1. Eliminate most of the costly placebo noise risk assessment and reporting processes in favour of effective actions, and use smartphones and other new technology to access information on low-cost engineering noise control solutions to plant noise that can be implemented at work.

2. Learn how to evaluate accurately the real-world attenuation of the hearing protection used and modify PPE procedures to increase performance. (Real-world means the actual level of protection from noise when PPE is worn at work, compared to the PPE manufacturer’s data on the attenuation provided, taking into account factors that will affect the level of attenuation – such as poor fitting of the hearing protection, interference from other PPE that is being worn and poor wear rates).

3. Consider using otoacoustic emission (OAE) audiometry in place of conventional pure tone audiometry.

Risk evaluation, actions and noise control

Avoid repeating placebo noise risk assessments

1. Don’t just repeat assessments (such as measuring noise levels from machines and tools and taking measurements to try to estimate workers’ personal noise exposure). Update only those elements where there have been plant or noise level changes. Note: HSE states you should implement noise risk reduction measures as soon as you know noise exposure is likely to be above 80dB(A). You don’t even have to measure noise before taking action.

2. Make a basic evaluation of the likely noise control options (i.e. engineering techniques for reducing noise from plant and machines) from available online information or by using INVC’s free email analysis service. INVC offers remote diagnosis of problem noise sources and a cost/benefit analysis of the most effective noise control options based on the best current technology, based on analysis of smartphone data sent to us, like short video clips and photos of noisy machinery. Click here for full details

3. Invest in a Noise Control Audit (NCA) so you can plan the most cost-effective risk reduction An NCA is an audit that generates a cost/benefit analysis of the noise control options (i.e. engineering measures) for loud plant and machinery based on current best practice. An NCA will provide information on the cost of the available noise control technology for plant and machinery and by how much it will reduce the noise exposure risk. Armed with this, you can then compare the cost of the engineering noise control measures for the plant and machinery against the financial and other savings from reduced PPE expenditure and use; reduced or eliminated audiometry; and reduced management time. This calculation can then be balanced against factors like the reduction in employees’ noise exposure, improved working conditions and productivity, to decide on the best engineering noise controls to invest in for the plant or machinery. An effective NCA can be very valuable because knowledge about modern methods for controlling noise from plant, machines and work processes is very poor, even amongst noise specialists – who an employer may commission to provide advice on noise control methods. Consequently, accurate, costed control advice in noise reports is rare.

Note: under the Control of Noise at Work Regulations, PPE cannot be used for long-term management of noise risks unless you can prove that noise control – such as modifying the work, process or machine to reduce the noise it produces – is impractical.

Peter Wilson: "Current noise risk reduction practices have not been effective despite the continuing expenditure on noise assessments and personal hearing protection."

Peter Wilson: "Current noise risk reduction practices have not been effective despite the continuing expenditure on noise assessments and personal hearing protection."

Simplifying noise control

The relationship between how much the noise can be reduced by (dB) and how much this reduces the risk of hearing damage (%) is as follows:

Hence, cutting noise from 97dB(A) to 90dB(A), for example, reduces the risk to employee hearing health by 80 per cent. The wearing of personal hearing protection by employees will still be required by law, but the risk from noise is 80 per cent lower and it is very much easier to achieve adequate protection from the PPE when noise levels are reduced to (or even below) 90dB(A).

Most organisations can use modern control methods to cut noise risks from plant and machinery by 50–90 per cent at little cost (or even at a profit) by consulting online engineering noise control case studies. Examples include the information available online from HSE and INVC, or using INVC’s free online noise control option analysis service, where we provide a cost/benefit analysis of the options, based on a smartphone video clip and photos of the noisy plant, machinery or process.

In fact, there are simple engineering solutions to many noise problems available online that can be implemented by any competent engineer, even those with no specialist knowledge of noise control. For example, see INVC’s ‘Detailed solutions to the 10 most common industrial noise problems’.

PPE performance – only 3dB attenuation when you expected 30dB

It has been known for decades that it is almost impossible to guarantee adequate protection from hearing damage when wearing PPE if noise levels are above 90dB(A).

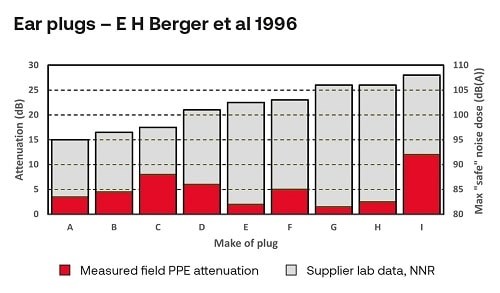

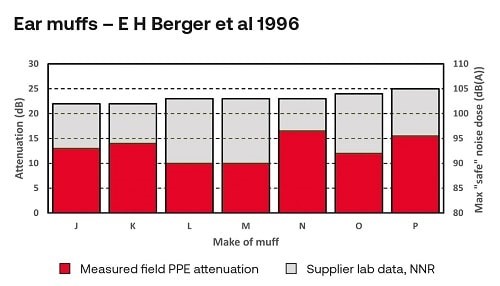

The two graphs below ('ear plugs' & 'ear muffs') prove that good quality PPE can provide adequate protection when the noise level is up to around 90dB(A) (it can reduce exposure to 80dB(A) or just under 80dB(A)) – provided the actual wearing of the PPE is well managed. In other words, 10dB attenuation is achievable – but not easily – using good quality PPE.

If more than 10dB attenuation is required from the PPE, it is difficult to guarantee adequate protection. Also, at around 95dB(A) – 100dB(A), it is virtually impossible to guarantee adequate protection from the PPE without introducing very stringent, time-consuming (and potentially impractical) controls.

So, when estimating how much attenuation will be provided by hearing protection, use the following guidelines:

- Earplugs: assume 10dB maximum attenuation, whatever the make or model

- Earmuffs: assume 17dB maximum attenuation, whatever the make or model

- Wear rate: this should be 100 per cent, but it rarely is in the real-world workplace. Could you prove your employees have a 100 per cent wear rate for their hearing protection? Every day?

Most organisations have hearing conservation programmes that are not based on this information. Consequently, millions of workers have suffered unnecessary hearing damage.

Let’s consider an example. A PPE manufacturers’ data says the hearing protection provides 25dB attenuation, so an employer assumes they are adequate for an exposure of 105dB(A). However, in actual fact, when used in a real-world workplace, the PPE only provides 3dB–10dB attenuation.

This means the PPE provides adequate protection for noise levels only up to 83dB(A) – 90dB(A). In short, the PPE provides between 3dB and 10dB attenuation, depending on the individual user. Hence one user will be safe up to 90dB(A) and another only up to 83dB(A) – if the in-ear level is to be kept to 80dB(A) or less.

So, in the example given of an employer wrongly assuming protectors have an attenuation of 25dB when exposure is 105dB(A), the workers will be at very high risk of hearing damage.

To improve the real-world hearing protection provided by conventional PPE the following approaches are vital (though they are often not implemented):

- You must have a wear rate audit system in place (a mechanism to evaluate the PPE wear rate). Otherwise, you cannot assess the performance of the PPE.

- You must provide PPE fit training (training for staff on how to correctly wear and use the protectors), particularly for earplugs.

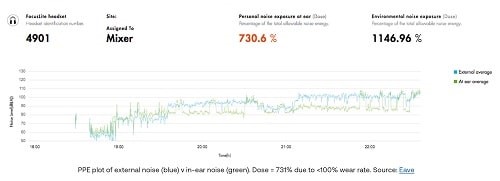

Alternatively, a potentially more cost and performance-effective option is to consider using the new generation of intelligent PPE that automatically logs both the wear rate and the attenuation. The PPE therefore provides verification that users are being sufficiently protected – or warns if action needs to be taken to ensure they are being protected.

The figure below shows the data collected by an example of this new generation of PPE, the FocusLite headsets from Eave, over a shift. The PPE plots the external and ‘at the ear’ noise levels inside the earmuffs of the user and calculates the noise dose. This provides automated verification of the degree of protection provided. See: www.eave.io/product

Health surveillance

Traditional audiometry is essentially a costly check-box exercise. Discuss...

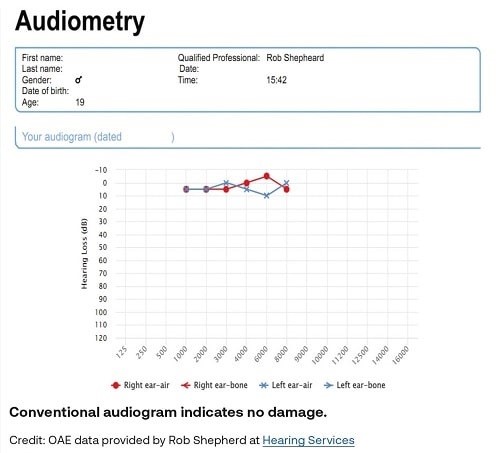

Conventional pure tone audiometry, or PTA, (conventional hearing checks for workers at risk of suffering hearing damage due to noise exposure), is a lagging indicator. It only detects hearing damage well after very substantial damage to the inner ear has already occurred after years of exposure.

A big question is whether employers ever use the results of audiometry to inform or amend their approach for reducing noise levels and exposure at work?

In fact, audiometry data is of little use in noise risk management. It is a gross and insensitive measurement of the individual’s overall hearing system and does not specifically measure the parts of the ear damaged by noise. Crucially, 50 per cent of the hair cell structures in the inner ear can be destroyed before audiometry will spot any changes, meaning conventional audiometry cannot spot the early stages of hearing damage.

Therefore, audiometry just catalogues failures in an employer’s approach to noise risk reduction years later. It is essentially a costly check-box exercise to comply with regulatory requirements.

In 2022 the British Society of Audiology recommended that audiologists use the newer otoacoustic emission (OAE) hearing tests in hearing conservation programs to assess the damage to hearing from noise, because “decreases in OAEs with sound exposure are typically detected before hearing loss is documented with pure tone audiometry”.

In other words, the new OAE hearing tests can detect the onset of slight hearing loss at a much earlier stage than conventional audiometry.

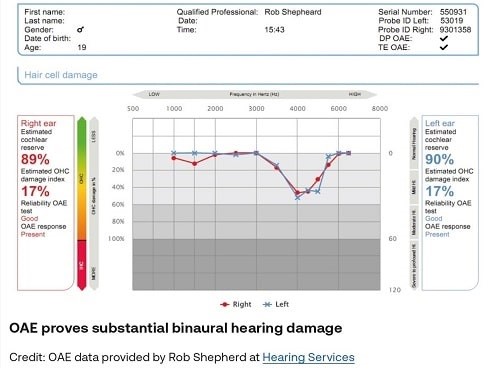

The OAE hearing tests that are now available can detect early damage – as shown in the figures in the ‘Audiometry’ and ‘OAE’ diagrams above (OAE data kindly provided by Rob Shepherd at Hearing Services).

Reviewing the two diagrams above, the conventional audiometric test data is ‘normal’ and shows no detectable hearing damage. By contrast, the OAE data shows that there is substantial damage in accord with the subjects’ experience.

Consequently, OAE can be an effective tool to monitor (and update if necessary) how well an employer’s hearing protection programme is working.

Think how motivational the following warning would be to encourage a worker to take precautions to protect their hearing: “You had nine per cent hearing damage last year – this year it is 15 per cent.”

Noise risk reduction – how to achieve Nil NIHL

The standard noise risk management procedures currently in use have failed the millions who have suffered avoidable noise-induced hearing damage. The damage includes a 9–27 per cent increased risk of dementia.

The changes detailed in this article can reduce these risks by 75–90 per cent at zero or negligible cost – or even at a profit – compared with current practices. It’s time to change...

Peter Wilson is Technical Director at the Industrial Noise and Vibration Centre (INVC)

For more information see:

invc.com

eave.io

hearingservices.co.uk

FEATURES

Turning sustainability compliance into business opportunity

By Alastair Loasby, Saffery LLP on 27 February 2026

Businesses that publicly demonstrate good sustainability performance can reap financial, reputational and other benefits, but it’s important to minimise the cost of any reporting on sustainability issues and to focus efforts on improving aspects of sustainability where the benefits outweigh the costs.

How to mitigate the hearing loss cost escalation tsunami

By Peter Wilson, Industrial Noise and Vibration Centre (INVC) on 06 February 2026

Employers need to adopt the latest and most effective noise risk evaluation and management measures, or face rapidly-rising compensation claims for noise-induced hearing loss at work.

Young drivers and work-related road risk: why employers must act now

By Simon Turner, Driving for Better Business on 06 February 2026

Young drivers have a higher risk of being involved in road collisions due to factors such as their inexperience, so when employing them to drive for work, it is vital they receive the right support to help them grow into safe professionals behind the wheel.