New research shows a majority of workers would be happy to be tested for drugs and alcohol at work to keep everyone safe, and developments in oral fluid testing kits mean the process is now faster and less invasive.

Features

Testing times

It was clear before the Covid pandemic shone a spotlight on the issue of drug and alcohol use in society, there was already a gradual increase in reports of substance use impacting the workplace. This includes both legal (i.e. prescribed) and illegal drugs, and alcohol consumption, all of which have the potential to impact on employee safety in the workplace.

Pros and cons of drug and alcohol testing in the workplace

It is therefore not surprising that more businesses are considering implementing a drug and alcohol testing programme. One of the main benefits of this type of programme is it promotes a safer working environment for employees, and this is particularly true for safety-critical industries involving work with hazardous chemicals, heavy machinery or driving, as impairment significantly increases the risks of a workplace accident.

Furthermore, a formal testing programme provides the employer an opportunity to offer support to employees who may be misusing alcohol or drugs – or have become dependent on or addicted to them – while improved education about the impact of drugs and alcohol on personal health (and safety at work) can promote a healthier workplace.

On the other side of the equation, money and resources must be committed to setting up and running a testing programme, and some employees might view this kind of policy as an invasion of their privacy.

A formal testing programme provides the employer an opportunity to offer support to employees who may be misusing alcohol or drugs. Photograph: Draeger Safety UK

A formal testing programme provides the employer an opportunity to offer support to employees who may be misusing alcohol or drugs. Photograph: Draeger Safety UK

Employee recognition of the need to keep everyone safe

However, employers can take heart that employees have a growing recognition of the role that everyone within a business must play in keeping colleagues safe. Independent research carried out earlier in the year for the 2022 Dräger Safety at Work report showed that there is growing recognition by employees of the important role of drug and alcohol testing in workplace safety.

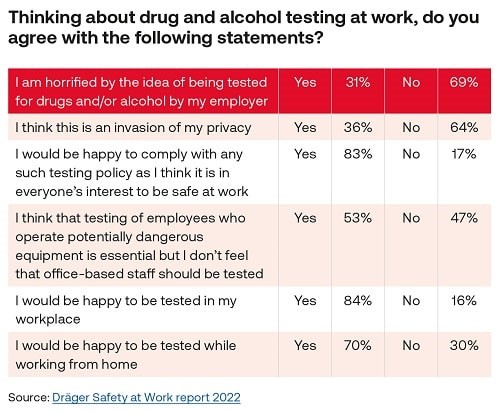

More than four in five (83 per cent) respondents stated that they would be happy to comply with drug and alcohol testing at work to ensure the safety of the workforce as a whole, and a perhaps surprising 70 per cent reported that they would be willing to be tested in their own home when working remotely (see table below).

Variation between industries

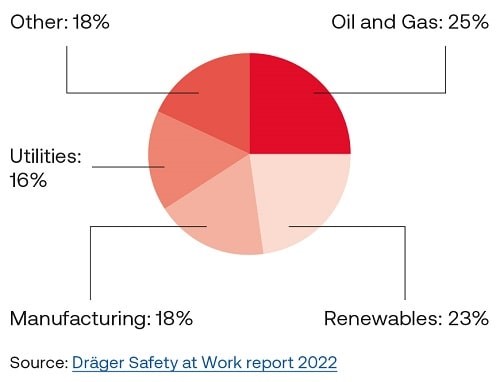

In terms of differences between industries, the utilities sector appears most accepting, with only a quarter (25 per cent) of those working in the utilities sector expressing horror at the idea of being tested for drugs and/or alcohol by their employer, compared with 40 per cent of those working in the oil and gas sector (see pie chart below).

Experience backs up the findings

The survey findings reflect Draeger Safety UK’s own experience of working with customers, indicating that there is a growing recognition that screening is part of a company’s comprehensive health and safety policy.

Furthermore, OdiliaClark, a specialist impairment risk management and wellbeing company whose services include independent drug and alcohol testing services to help businesses maintain a safe working environment, says that its experience of working with UK businesses backs up the research findings. David Whiffin, managing director, said: “In the main, employees see testing as a positive activity. They understand that testing is there as a safety net to support the many, not penalise the few.

“It’s important that whatever the case for introducing a screening programme, the policy itself is fair and consistent, the procedures and process used are in line with current guidelines and best practice, and that the equipment and subsequent analysis are high-quality and accurate. The benefits of a good policy and programme should complement the overall approach to health and safety in the workplace and should be deployed in a non-punitive manner.”

Scope of testing

The research for the 2022 Dräger Safety at Work report further shows a slight split between those who feel that testing should only apply to employees operating potentially dangerous equipment rather than office workers, with 53 per cent feeling that this should be the case and 47 per cent disagreeing. This appears to suggest that there is a preference that policies should be applied equally across the workforce, rather than singling out specific functions or roles.

Impairment and driving for a living

One significant element of this type of approach means that vocational drivers would be included in testing programmes. We are generally familiar with the impact of drinking and driving but recent figures from the Department of Transport indicate increased prevalence for drug driving rather than drink driving, with drug driving responsible for 22 per cent of all fatalities on the road, compared with 18 per cent for drink drivers.

At the same time, the Parliamentary Advisory Council for Road Safety (PACTS) recently issued a statement in which they suggest that illegal drug use by drivers could be a factor in around 200 road deaths in the UK each year – with laboratory blood tests in drug driving prosecutions showing that cannabis is the most common drug involved. With recent discussions about the legalisation of cannabis, there is a concern that this may lead to further drug driving and road casualties.

Explain to employees why the policy is being introduced and to provide education on the significance to workplace safety. Photograph: Draeger Safety UK

Explain to employees why the policy is being introduced and to provide education on the significance to workplace safety. Photograph: Draeger Safety UK

What is impairment?

If we come back to an early point made in this article, there have been many reports and surveys, particularly since Covid, on the increase in drug and alcohol consumption in the population.

A 2022 report by Delamere on drug and alcohol use suggests that in the past few years drink and drug usage, particularly drinking, has become normalised. During the pandemic and beyond, the report revealed that many individuals use alcohol to alleviate stress, whether from the stress and loss endured during Covid or to the current cost of living crisis. More than half of the respondents (56 per cent), stated that alcohol in particular helps them to relax while an alarming fifth (21 per cent), said that it helped to diminish feelings of stress but acknowledged that this led to a vicious circle of alcohol abuse, often leading to increased anxiety.

Prescription medication

It is also evident that the increased prescribing of legal drugs, which in part may be attributed to treatment of mental health and general wellbeing, is also part of the wider increase in drug and alcohol consumption. And while it can be seen as positive that there is a growing acceptance and awareness of the importance of mental health alongside physical health, there are, nevertheless, implications for safety at work, regardless of the motivation.

It’s important to recognise that prescription medicines, such as benzodiazepines (which treat common medical issues such as depression) have the potential to impair the person taking them, and in turn, the potential to impact safety in the workplace.

Common side effects from such drugs can include drowsiness, dizziness, loss of balance, confusion or memory loss. Clearly this type of side effect has very real and practical impact, particularly in safety-critical jobs, whether operating heavy machinery or simply driving a colleague to a meeting. It is therefore vital that employees are given appropriate support, and ensure they keep taking their medication, while sensitively managing any possible risks to workplace safety.

Workplace drug and alcohol policies

The Health and Safety Executive (HSE) is clear that all employers have a legal duty to protect employees’ health, safety and welfare. Having a drug and alcohol policy which tests for all substances that have the potential to impair safety is increasingly seen as an important part of fulfilling this obligation and protecting all employees.

Testing in practice

Firstly, it is important to recognise that drug and alcohol testing is a highly sensitive area and employees may have concerns around the topic, so it is important to:

- Explain to employees why the policy is being introduced and to provide education on the significance to workplace safety – for example, someone under the influence of drugs could pose a risk to themselves, to others in the workplace or to the general public, rather than the company imposing on an individual’s private life.

- Consider an amnesty period, a defined length of time during which employees can approach HR colleagues without judgement to alert them to any drug or alcohol use that may prove problematic once the testing programme is brought in. This is particularly important for employees who may be taking prescribed medication.

- Decide what type of testing to introduce, particularly for drug testing where the options range from oral fluid testing (which as explained below is not dissimilar to Covid tests), to a full laboratory test, or incorporating a combination of both, with the former being used for screening and the latter if there is a concern that drugs are impacting on work performance.

- Manage the testing process itself with care, dignity and respect.

New technology in workspace testing?

With the advent of lateral flow and PCR testing for Covid, employers and employees are becoming more familiar with the concept of oral fluid testing, and one way of introducing drug and alcohol testing into the workplace is using new techniques which offer fast and less invasive tests.

There have been significant improvements in oral fluid testing in recent times and in contrast to urine and blood tests, the advantages include ease of use, non-invasiveness, observable sample collection, difficulty to adulterate and demonstration of recent drug use.

Against the backdrop of increased drug and alcohol use, oral fluid testing is increasingly used in workplace environments. It would be wrong to suggest that oral fluid testing offers a replacement for blood and urine testing; but it is a highly valuable tool for health and safety professionals for occasions when detection of relatively recent use of drugs is sought in a non-invasive manner.

With employees much more familiar with lateral flow and PCR tests, and ever advancing improvements in more sensitive and reliable detection, this form of testing is set to become more common in the future.

Encouragement for ongoing healthcare safety

In conclusion, it is encouraging that employers are taking health and safety issues more seriously where they relate to impairment resulting from drugs and alcohol and also that there is a modernisation in attitude towards personal responsibility for safety. Drug and alcohol use and misuse pose a tremendous challenge to business and to its ability to operate productively and to safeguard employees’ health and wellbeing.

Testing programmes are increasingly being explored by forward-thinking employers who recognise their importance as part of a holistic approach to health and safety in the workplace in 2022 and beyond.

Ian Gil-Rodriguez is marketing manager – impairment at Draeger Safety UK

FEATURES

A year on – what have been the developments in competence management and the golden thread?

By Sofie Hooper, Association for Project Safety and Anthony Taylor, Resolve Risk Ltd on 03 July 2025

Last July the authors published an article in Safety Management where we looked at the expectations for those responsible for managing competence and those creating and managing the golden thread. In this edition we provide an update on both these key requirements of the Building Safety Act/Fire Safety Act’s ‘new regulatory regime’ including for higher-risk buildings (HRBs).

Stars, stripes and safety

By Belinda Liversedge on 02 July 2025

It seems like America today is rarely out of the news, particularly since President Trump won his second term. Our ‘special relationship’ with America has continued, with the country a strong pipeline for inspiration, products and trends.

The hidden risks of lithium-ion batteries

By Adrian Simmonds, QBE Europe on 01 July 2025

With UK fire services now tackling at least three Li-ion battery fires a day, it’s clear that stronger regulation and enforcement is urgently required to prevent the sale, use and modification of poor-quality and potentially dangerous batteries used in e-bikes and scooters.